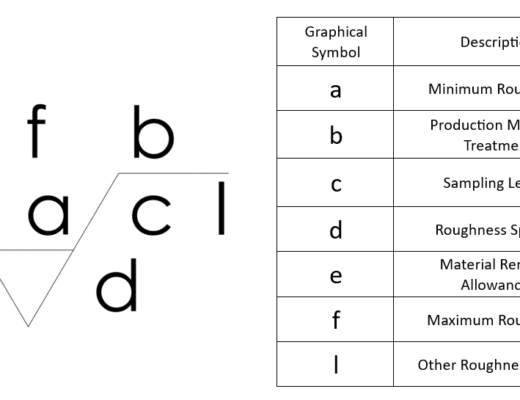

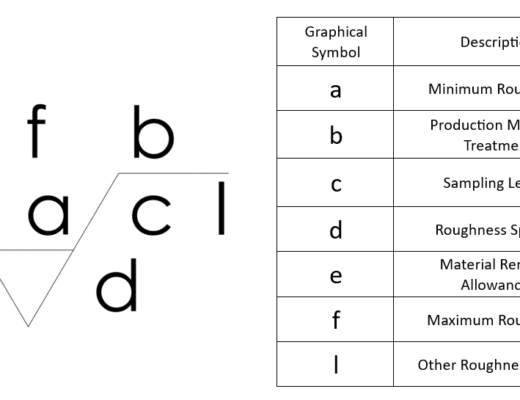

With precision being a key factor in manufacturing and engineering industries, surface roughness plays a vital role in ensuring product quality. To achieve this precision, […] Read More

With precision being a key factor in manufacturing and engineering industries, surface roughness plays a vital role in ensuring product quality. To achieve this precision, […] Read More

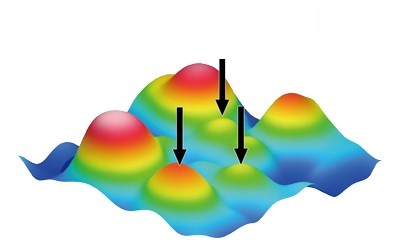

Have you ever scratched your head trying to understand White Light Interferometry, for profile and roughness measurement? Simply put, White Light Interferometry (WLI) is like […] Read More

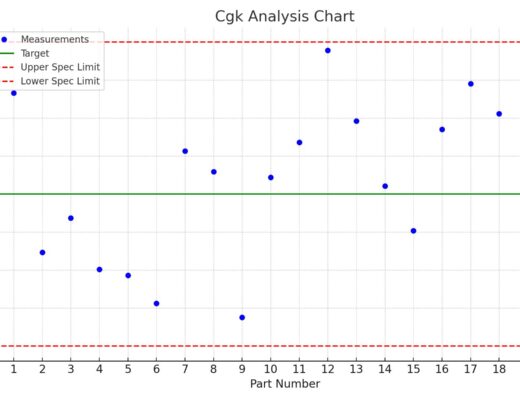

In industrial measurements, precision and accuracy are paramount. This guide demystifies gage repeatability and the crucial capability indices Cg and Cgk, enhancing your grasp on […] Read More

In today’s market, where counterfeit goods are becoming increasingly sophisticated, it’s crucial to know that the Mitutoyo products you’re purchasing or already own are genuine. […] Read More

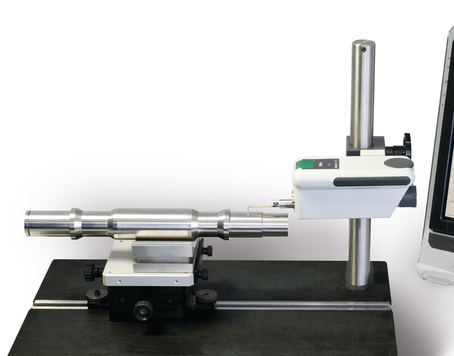

Do you need to precisely measure surface finish? For inspection purposes, engineers and quality inspectors rely on a device known as a profilometer, also known […] Read More

Measuring the contour of an object can include capturing its shape, outline, or surface geometry. The method can vary in complexity based on the precision […] Read More

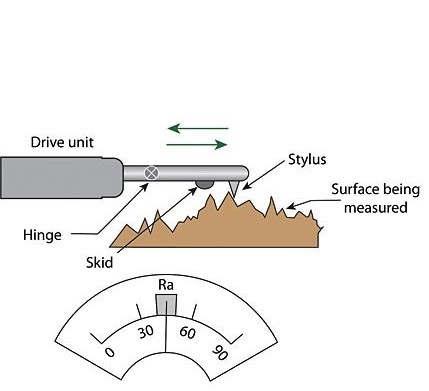

When it comes to measuring surface finish, engineers and quality inspectors rely on two types of probe tips—skidded and non-skidded. Skidded probes utilize a diamond-tipped […] Read More

In the precision-driven world of manufacturing, master gages and reference parts play a critical role. They are the benchmarks that ensure the accuracy and consistency […] Read More

A machinist’s precision tools are the backbone of quality control in industry, and micrometers are at the heart of this precision. The Mitutoyo QuantuMike is […] Read More

In the complex world of manufacturing, keeping track of every component and process is crucial. This is where the concept of “traceability” plays a vital […] Read More