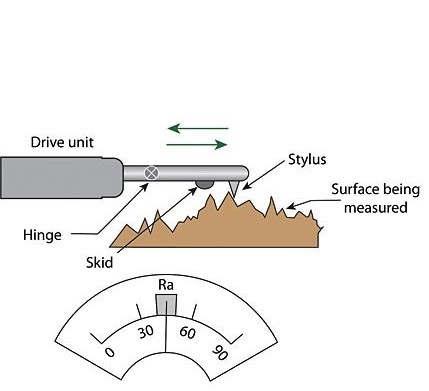

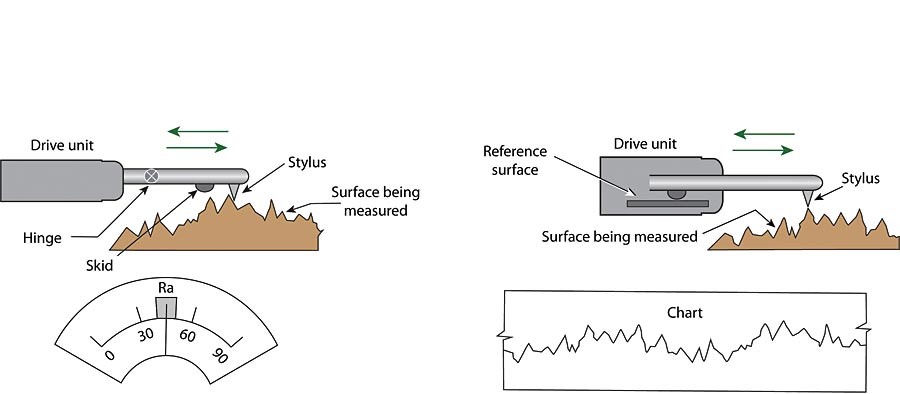

When it comes to measuring surface finish, engineers and quality inspectors rely on two types of probe tips—skidded and non-skidded. Skidded probes utilize a diamond-tipped stylus supported by a metal skid that rests on the workpiece, making the workpiece itself the reference surface. In contrast, skidless (non-skidded) probes utilize an internal precision rail to provide the reference, enabling them to be used with high-end surface measuring systems for comprehensive analysis, including measurements of waviness and form parameters in addition to roughness.

Skidded Probes

Skidded probes are commonly used for simple roughness measurements such as Ra and Rz. They come in various types, each designed for specific applications. For example, there are probes tailored to measure surface finish at the bottom of grooves or along sharp edges. The choice of probe depends on factors such as part characteristics and the length of the surface to be measured. Skidded probes can be classified into two main types: longitudinal and lateral.

- Longitudinal Probes: These probes have a skid that runs parallel to the length of the measurement probe. The skid surface is positioned either in front of or behind the measurement stylus and makes direct contact with the surface to be measured. Longitudinal probes require a minimum surface length to operate effectively and prevent erroneous results.

- Lateral Probes: Lateral probes have a skid that runs across the length of the measurement probe. The skid surface is positioned to the left or right of the probe. These probes are suitable for areas with short measurement land areas or close to a shoulder.

Skidless Probes

Skidless probes offer the advantage of measuring on both flat and radiused surfaces. They lack a skid accompanying their movement and utilize built-in filters to separate waviness measurement from roughness. Skidless probes are typically more expensive than skidded models and are commonly used in laboratory or inspection environments.

Choosing Between Skidded and Skidless Probes

Selecting the appropriate type of probe depends on the surface characteristics and measurement requirements. Skidded probes are ideal for flat surfaces, whereas skidless probes are suitable for both flat and radiused surfaces. While skidded probes are generally more affordable, they have a limited range of travel, skidless probes offer greater range of travel and better accuracy and repeatability.

Examples

- Skidded Probes: Suitable for flat surfaces, where Ra is needed and limited probe travel is not a factor. Imagine a theoretical surface like a flat vinyl record with grooves and the grooves are measured from the center of the record, outward.

- Skidless Probes: Necessary for measuring radiused surfaces, where a lot of travel is needed, or profile and waviness parameters are called out on the drawing. In our vinyl record example, a skidless probe lets you measure the warped vinyl album, where skidded probes may not provide accurate results of the longer waveforms.

Key Differences

- Skidded Probes: Feature a small skid or “foot” accompanying the probe’s movement, typically priced lower and more portable because the skid “ties” the probe to the surface. Handheld units are skidded instruments.

- Skidless Probes: Lack a skid, but are capable of measuring radiused surfaces, higher in price and less portable. Not possible to make handheld or robot measurements without other fixturing.

Popular Models

- Skidded Models: Mitutoyo SJ-210, or MarSurf PS10.

- Skidless Models: Mitutoyo SJ-410, Mitutoyo SJ-500, or MarSurf M400. In summary, skidded probes are suitable for flat measuring surfaces, while skidless probes offer versatility for both flat and radiused surfaces. Understanding the differences between these probe types is crucial for selecting the appropriate tool for accurate surface measurements.

Skidded probes are suitable for flat measuring surfaces and may be handheld, while skidless probes offer versatility for both flat and radiused surfaces, but require a stand and table. Understanding the differences between these probe types is crucial for selecting the appropriate tool for accurate surface measurements.

If you have questions about when a skidded or skidless probe is needed, or what surface roughness and profile parameters can be measured with each type, drop us a line. When you are ready to buy a profilometer, we can provide expert advice for YOUR parts and process! Fill out the contact form and our Profile and Roughness Knowledge Expert will contact you. Your information will not be used for any other purpose and will not leave our secure servers without your permission. If you’d rather just email us, you can do so at MajorGageMail@gmail.com